Sleeve Balun Costruction Details

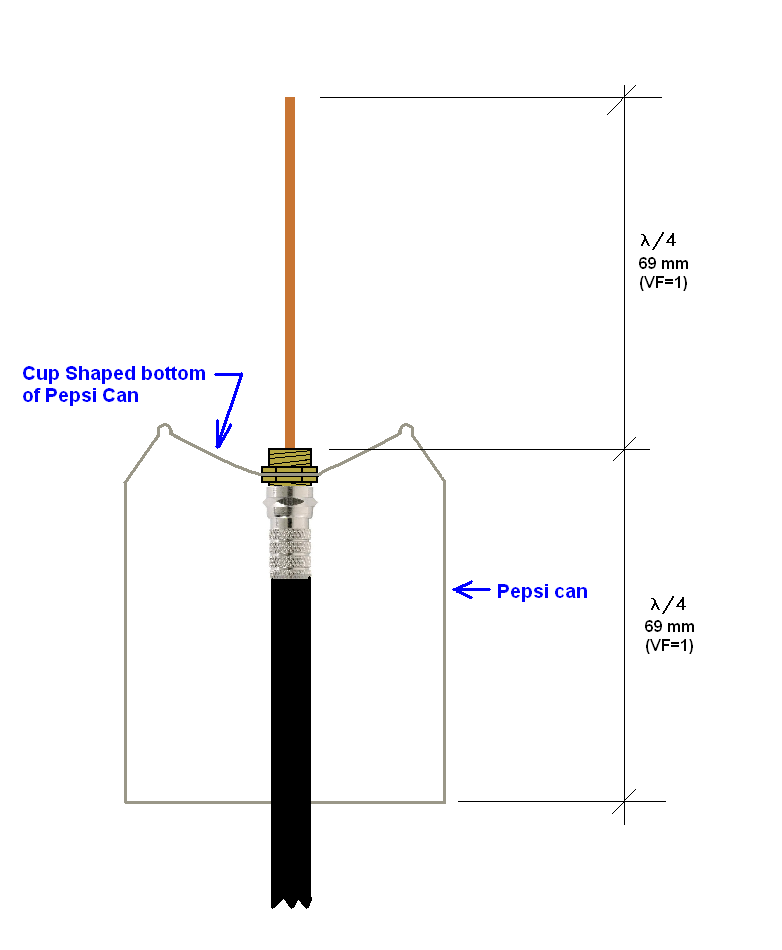

..... And here are the construction details of the Sleeve....

The length of Sleeve (i.e. cut length of Pepsi tin) is 6.9 cm (λ/4 in air VF=1)

picture 1 of 5

DSC03167.jpg

picture 2 of 5

DSC03168.jpg

picture 3 of 5

DSC03170.jpg

picture 4 of 5

DSC03171.jpg

picture 5 of 5 - Fully Assembled

DSC03172.jpg

..... And here are the construction details of the Sleeve....

The length of Sleeve (i.e. cut length of Pepsi tin) is 6.9 cm (λ/4 in air VF=1)

picture 1 of 5

DSC03167.jpg

picture 2 of 5

DSC03168.jpg

picture 3 of 5

DSC03170.jpg

picture 4 of 5

DSC03171.jpg

picture 5 of 5 - Fully Assembled

DSC03172.jpg

Comment